Top 10 Tips for Choosing the Right IBC Containers for Your Needs

When it comes to selecting the right Intermediate Bulk Containers (IBC containers) for your specific needs, gaining insights from industry experts can be invaluable. John Smith, a renowned specialist in bulk packaging solutions, emphasizes, "Choosing the correct IBC container is crucial; it not only enhances operational efficiency but also ensures the safety and integrity of your materials." With an array of options available, making the right choice can feel overwhelming.

Understanding the key features and benefits of different IBC containers is essential for anyone involved in the transportation and storage of liquids and granulated substances. This guide aims to provide a comprehensive overview of the top considerations to keep in mind when choosing IBC containers, tailored to support your operational requirements while maximizing effectiveness. By looking closely at factors such as material compatibility, capacity, and design specifications, you can make informed decisions that align perfectly with your business objectives.

Understanding IBC Containers: Types and Specifications Overview

When selecting Intermediate Bulk Containers (IBCs) for your storage and transportation needs, it’s essential to understand the various types and specifications available.

IBCs come in different materials, such as high-density polyethylene (HDPE), stainless steel, and carbon steel, each suited for specific applications.

According to recent industry reports, the market for IBCs is projected to grow by approximately 5.4% annually, driven by increasing demand in industries like chemicals, food and beverage, and pharmaceuticals.

Understanding the specifications—such as capacity, weight, and compatibility with different substances—will help in making an informed choice.

One key tip when choosing IBC containers is to assess the compatibility of the container material with the contents. For instance, HDPE IBCs are ideal for non-hazardous liquids, while stainless steel containers provide a more robust solution for hazardous or corrosive substances. Additionally, consider the capacity you require; IBCs typically hold anywhere from 275 to 330 gallons.

Ensuring the right fit can prevent leaks and spills, subsequently enhancing safety and compliance.

Another important consideration is the design and ease of handling. Some IBCs come equipped with features like integrated pallet bases and drain valves, making them easier to stack, transport, and empty.

As per the American National Standards Institute, compliant IBCs can significantly reduce the risk of accidents during handling.

Ensuring that the container you choose meets industry safety standards will ultimately lead to better operational efficiency and risk management.

Assessing Size and Capacity Needs for Optimal Transport Efficiency

When selecting the appropriate Intermediate Bulk Container (IBC) for your transportation needs, assessing the size and capacity is crucial for enhancing transport efficiency. IBC containers come in various sizes, typically ranging from 110 gallons to over 300 gallons, which can directly affect your logistics and operational costs. According to a report by the International Maritime Organization, the right sizing of containers can reduce shipping costs by up to 20% due to increased payload optimization. Understanding the load capacity not only aids in compliance with safety standards but also helps prevent unnecessary trips, thereby lowering carbon emissions and improving overall supply chain sustainability.

It's essential to evaluate your specific requirements before making a choice. For instance, industry standards indicate that using IBCs with optimal capacity for your product type can significantly reduce losses during transport due to spillage or damage. A study conducted by the United Nations Conference on Trade and Development highlights that 40% of waste in supply chains can stem from improper sizing of packaging solutions. By assessing your size and capacity needs effectively, you can ensure that your operations are both cost-efficient and environmentally sustainable, leading to improved performance across your logistics network.

Material Selection: Comparing Polyethylene, Steel, and Composite Options

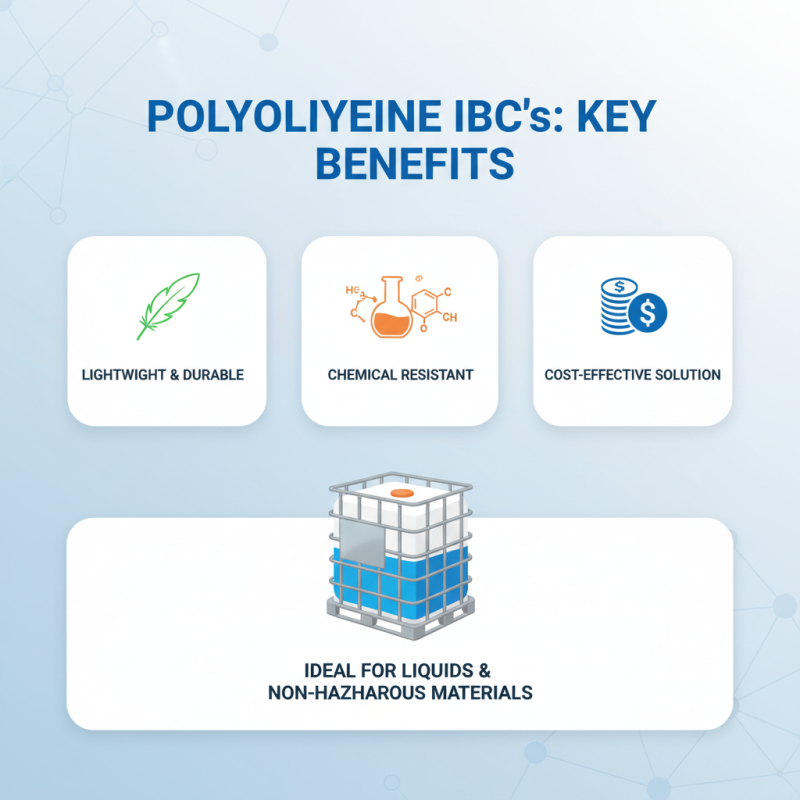

When selecting Intermediate Bulk Containers (IBCs), material choice is a crucial factor that significantly impacts functionality and durability. Polyethylene is a popular option due to its lightweight nature, resistance to corrosion, and ability to withstand a range of chemicals. This makes it particularly suitable for storing and transporting various liquids, including those that are non-hazardous. Additionally, polyethylene IBCs are often more affordable compared to other materials, making them a cost-effective solution for many industries.

On the other hand, steel IBCs offer advantages in terms of strength and longevity. They are ideal for heavy-duty applications and can handle extreme conditions and high-pressure environments. Steel containers are also more efficient for the long-term storage of bulk goods, thanks to their robustness and resistance to impact damage. However, they may require additional treatment to resist rust and corrosion, which can be a consideration for companies dealing with moisture-sensitive products.

Composite IBCs combine the benefits of both polyethylene and steel, featuring an outer steel frame and an inner plastic liner. This design provides exceptional protection against punctures and damage while maintaining a lightweight profile. Composite options are becoming increasingly popular for organizations looking for versatile, durable, and efficient storage solutions. Ultimately, understanding the unique properties of these materials can guide businesses in choosing the right IBC containers to meet their specific needs.

Compliance Standards: Ensuring Safety and Durability in IBC Use

When selecting Intermediate Bulk Containers (IBCs), understanding compliance standards is crucial for ensuring safety and durability in their use. Regulatory requirements may vary by industry and location, but key standards typically revolve around the materials used in construction, the design of the containers, and their intended applications. For instance, IBCs made from high-density polyethylene (HDPE) must resist corrosion and withstand the stresses of handling and transportation, ensuring they meet the required safety qualifications. Familiarizing oneself with guidelines provided by relevant authorities can prevent potential hazards associated with container failure.

Moreover, durability is paramount in IBC selection. Containers should undergo rigorous testing to confirm they can handle various conditions, from extreme temperatures to heavy impacts. In addition to physical integrity, considering factors such as UV resistance and chemical compatibility is essential. Assessing the specifications pertaining to weight limits and stacking protocols can further enhance safety during storage and transport. By prioritizing compliance with industry standards, users can make informed choices, ultimately leading to enhanced operational efficiency and reduced risks associated with IBC usage.

Top 10 Tips for Choosing the Right IBC Containers for Your Needs - Compliance Standards: Ensuring Safety and Durability in IBC Use

| Tip Number |

Tip Description |

Compliance Standard |

Recommended Material |

Estimated Lifespan |

| 1 |

Determine the Specific Application |

UN Standards |

High-Density Polyethylene (HDPE) |

10-15 years |

| 2 |

Assess Compatibility with Stored Materials |

FDA Compliance |

Stainless Steel |

15-20 years |

| 3 |

Choose the Right Size and Capacity |

AIB International Standards |

Polypropylene |

5-10 years |

| 4 |

Check for Certifications |

ISO 9001 |

Composite Materials |

10-15 years |

| 5 |

Consider the Weight of the Container |

ASTM Standards |

Wood |

2-5 years |

| 6 |

Evaluate Safety Features |

HSE Guidelines |

Steel |

15-25 years |

| 7 |

Investigate Ancillary Equipment |

Pallet Compliance |

Plastic |

5-10 years |

| 8 |

Plan for Storage and Transportation |

IMDG Code |

Coated Steel |

10-20 years |

| 9 |

Consider Customization Options |

BRC Global Standards |

Reinforced Plastic |

5-15 years |

| 10 |

Review Cost vs. Value |

EPA Regulations |

Aluminum |

20-30 years |

Cost-Benefit Analysis: Budgeting for Purchase versus Rental Options

When deciding on the right IBC containers for your needs, a crucial consideration is the cost-benefit analysis of purchasing versus renting. Buying containers can be a significant upfront investment. It is essential to take into account not only the purchase price but also the long-term storage, maintenance, and potential depreciation of the asset. Companies with predictable, ongoing usage of IBC containers may find that purchasing is more economical in the long run, especially when considering the benefits of having dedicated containers readily available.

On the other hand, renting IBC containers can offer considerable flexibility and cost savings for businesses with fluctuating needs or short-term projects. With rental agreements, companies can avoid the large initial expenditure and eliminate the burden of maintenance. This arrangement often allows for a variety of container options, ensuring you can choose the right type based on your specific requirements without being locked into a long-term commitment. The key is to assess your operational needs and budgetary constraints to determine which option will yield the highest value for your situation.

Cost-Benefit Analysis of IBC Containers: Purchase vs Rental Options