Why Choose an IBC Water Tank for Your Storage Needs?

In an era where efficiency and sustainability are paramount, choosing the right water storage solution is more critical than ever. The IBC water tank has emerged as a reliable choice for both commercial and residential needs, offering versatility and durability. According to recent industry reports, the global demand for IBC tanks is projected to grow at a CAGR of 5.1% from 2021 to 2028, highlighting their increasing relevance in various sectors including agriculture, chemical processing, and construction.

Experts in the field, such as Dr. Emily Carter, a leading authority on water storage systems, emphasize the importance of adopting efficient solutions. She states, "The IBC water tank stands out for its efficiency and space-saving design, making it an ideal choice for diverse storage applications." The IBC water tank, with its robust polyethylene construction and stackable design, addresses the needs of modern storage requirements while ensuring safe and effective water containment. By selecting an IBC water tank, users can optimize their storage capabilities while contributing to a more sustainable approach to resource management.

Benefits of IBC Water Tanks for Efficient Liquid Storage Solutions

IBC water tanks, or Intermediate Bulk Containers, are gaining popularity for a variety of liquid storage needs. One of the primary benefits of using IBC tanks is their robust design. Made from high-density polyethylene or steel, these tanks are built to withstand harsh environmental conditions while ensuring the safety of the liquids stored within. Their square shape maximizes space efficiency, allowing for easy stacking and storing, which is particularly advantageous for businesses with limited storage facilities.

Another significant advantage of IBC water tanks is their versatility. They can be used for storing everything from water to agricultural chemicals, food-grade liquids, and solvents. This flexibility makes them an ideal choice for various industries, including agriculture, construction, and manufacturing. Furthermore, IBC tanks come equipped with a range of fittings and valves, enabling easy dispensing and transfer of liquids. This efficiency not only streamlines operations but also reduces the risk of spills and contamination, thereby enhancing safety and compliance within the workplace.

Understanding the Structure and Design Features of IBC Tanks

Intermediate Bulk Containers (IBCs) are remarkably designed for

efficient storage and

transport of liquids and

bulk materials. Their structure typically consists of a cubic frame that offers strength and stability while allowing for optimal space utilization. The rigid outer frame is usually made of robust plastic or metal, which protects the inner liner made of materials such as polyethylene. This dual-layer construction makes IBC tanks highly resilient, providing a secure method for holding various non-hazardous liquids, chemicals, and even food-grade substances.

One of the distinguishing design features of IBC tanks is their

stackable nature, allowing users to

maximize storage space. This design not only facilitates efficient

transportation but also enables easier handling during loading and unloading.

Additionally, many IBC tanks come equipped with a variety of outlet options

and fittings that cater to different dispensing requirements, further enhancing

their versatility. Their modular design promotes ease of cleaning and maintenance,

making IBCs suitable for repeated use.

Overall, the thoughtful engineering of IBC tanks ensures they meet diverse

storage needs while adhering to safety

and efficiency standards.

Comparative Analysis of IBC Tanks vs Traditional Storage Solutions

When considering storage solutions, the debate between

Intermediate Bulk Containers (IBCs) and traditional storage options such as drums or tanks often comes to the forefront.

IBCs can hold up to 1,100 liters of liquid, which is significantly more than standard 200-liter drums.

According to a report by the International Storage Tank Standards Group, the large capacity of IBCs can lead to a reduction in the frequency of refilling and handling,

thus saving time and reducing labor costs.

In addition to their volume benefits, IBC tanks are designed for optimal space efficiency. Their stackable nature enables better use of warehouse space compared to cylindrical drums, which occupy more ground area for the same volume.

The Environmental Protection Agency (EPA) has noted that reducing wasted space in storage solutions can enhance operational efficiency by up to 30%.

This aspect makes IBCs especially appealing for businesses looking to optimize their storage footprint.

Tips: When transitioning to IBCs, ensure proper training for staff on handling and maintaining these tanks to maximize their lifespan.

Additionally, always consider your fluid's compatibility with the IBC materials to avoid contamination or degradation of the tank.

Regular inspections are essential to maintain compliance with safety standards and to ensure the integrity of the stored materials.

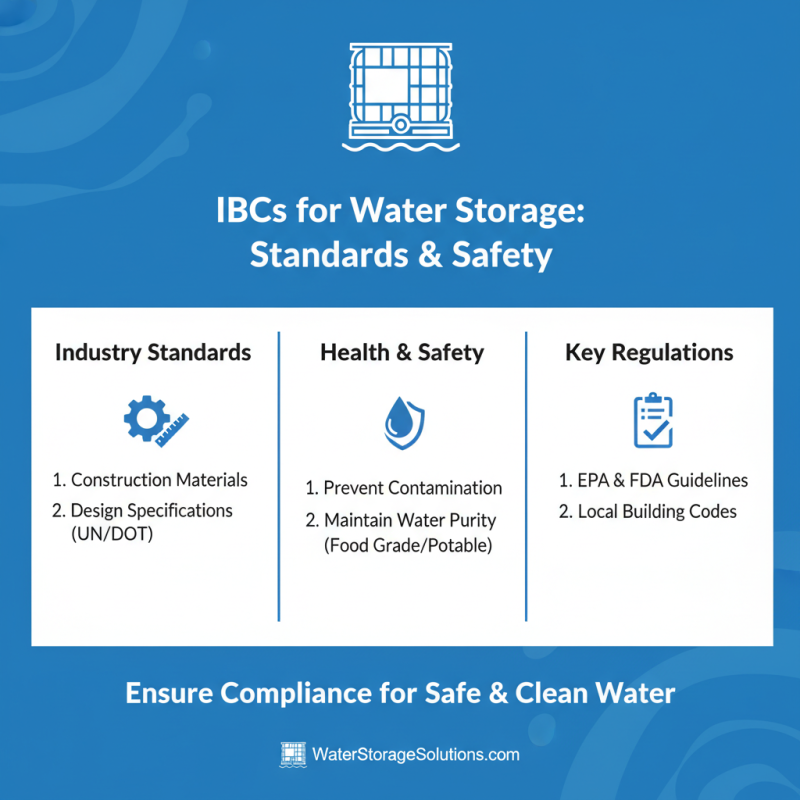

Industry Standards and Regulations for IBC Water Tank Usage

When considering the use of Intermediate Bulk Containers (IBCs) for water storage, understanding the industry standards and regulations that govern their usage is paramount. IBC tanks are designed to meet stringent specifications established by regulatory bodies, ensuring safe transport and storage of liquids. These standards often pertain to construction materials, labeling, and compatibility with the substances stored. For water storage, compliance with health and safety regulations is crucial, as it ensures that the water remains clean and uncontaminated throughout its lifecycle.

In addition to structural integrity, IBCs must adhere to regulations regarding maintenance and inspection. Regular checks are mandated to monitor for signs of wear, leakage, or contamination, which can impact the quality of the stored water. Many jurisdictions require owners to keep a maintenance log to demonstrate compliance with these regulations. Furthermore, facilities storing large quantities of water in IBCs may also need to follow environmental guidelines that dictate how to manage spills or leaks, safeguarding both human health and the environment. By understanding these industry standards, users can ensure that their IBC water tanks are utilized effectively and responsibly.

Cost-Effectiveness and Longevity of IBC Water Tanks in Various Applications

When it comes to selecting a water storage solution, Intermediate Bulk Containers (IBCs) have emerged as a preferred choice for various industries. One of the most compelling reasons for this preference is their cost-effectiveness. According to a report by the International Water Association, the initial investment in an IBC water tank can be approximately 20-30% lower than that of traditional tanks, making them attractive for businesses looking to manage operational costs efficiently. Additionally, their stackable design allows for optimized shipping and storage, further reducing logistical expenses.

Another key advantage of IBC water tanks is their longevity. Industry studies indicate that high-quality IBCs can last for over 10 years when used correctly, significantly longer than many traditional storage solutions which may require replacement every 5-7 years. This durability not only contributes to lower replacement costs over time but also minimizes the environmental impact associated with frequent replacements. The versatility of IBCs is evident in their applications, ranging from agriculture for irrigation needs to industrial uses for chemical storage, demonstrating their adaptability and resilience in varied conditions. As businesses increasingly seek sustainable and economical solutions, IBC water tanks stand out as a prudent choice, merging long-term savings with robust performance.